como funciona a

válvula termostática

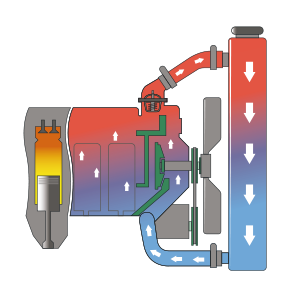

A válvula termostática é geralmente localizada na saída do motor para o radiador, integrada ao sistema de mangueiras de líquido de arrefecimento. Seu núcleo consiste em uma cera termossensível encapsulada que se expande ou contrai em resposta às variações de temperatura. Quando o motor está frio, a cera se contrai, abrindo parcialmente a válvula e permitindo que o líquido de arrefecimento circule apenas no interior do bloco do motor, acelerando o aquecimento.

Conforme a temperatura do motor atinge o ponto ideal, a cera se expande, fechando a válvula parcialmente ou completamente, redirecionando o líquido de arrefecimento para o radiador. Essa regulação dinâmica assegura que a temperatura do motor permaneça dentro dos limites ideais de operação.

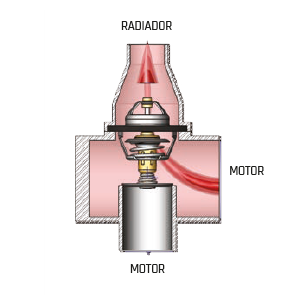

Termostato Fechado

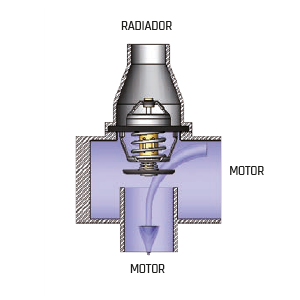

termostato aberto

CIRCULAçÃO

Válvula Termostática de Abertura Direta

Este tipo de válvula termostática é o mais comum e funciona através da expansão de uma cera ou de um elemento bimetálico.

Quando a temperatura do líquido de arrefecimento atinge um determinado ponto, a cera ou o elemento bimetálico se expande, forçando a válvula a abrir e permitindo que o líquido de arrefecimento flua para o radiador.

Conforme a temperatura cai, a cera ou o elemento bimetálico se contrai, fechando a válvula e reduzindo o fluxo de líquido de arrefecimento para o radiador.

Importância da

válvula termostática

Mantendo a temperatura do motor constante, a válvula termostática contribui para a eficiência térmica, otimizando a combustão e reduzindo o consumo de combustível.

A operação na faixa de temperatura correta melhora o desempenho do motor, reduzindo o desgaste prematuro e aumentando a vida útil dos componentes.

O controle preciso da temperatura do motor contribui para a redução das emissões, pois as reações químicas na câmara de combustão são mais eficientes a temperaturas específicas.

Facilita o aquecimento inicial do motor em condições de frio, proporcionando conforto ao condutor e minimizando o desgaste durante o período de aquecimento.

DEDICATED TO INNOVATION

The Fabrik Automotive Center was established with a singular purpose: to provide specialized material and application expertise to assist our automotive customers. Equipped with cutting-edge technology and backed by decades of experience, our commitment is to aid automotive engineers in assessing potential applications and addressing the current challenges and opportunities, such as cost savings, weight reduction, formability, crash energy management, and material availability.

Lightweight Integrated Components

Stainless steel’s reputation for lightweight strength makes it a preferred material choice in various automotive applications. It excels in parts crucial for a car’s performance, including the fuel tank, chassis, and even the bumper.

Additionally, stainless steel is crucial in crafting numerous small components like tubes, brackets, springs, clamps, flanges, and other intricate parts. These more minor elements support the vehicle, connect components, and form the car’s overall structure.

Car Frame

Stainless steel seamlessly blends durability and elasticity, making car frames crafted from this material possess similar strength to many other metal alloys while also being notably lighter. Opting for stainless steel translates to a robust yet lightweight frame, considered one of the most effective supports for a vehicle.

In rigorous testing of austenitic stainless steel grades, the material’s hardening rate was observed to correlate with the deformation rate. In the context of automobiles, stainless steel can absorb more force compared to the typical structural steel often utilized.

Corrosion Resistant Parts

Stainless steel is essential for vehicles, offering corrosion resistance in the face of dirt and adverse weather conditions. It’s a top choice for parts like exhaust systems, which are prone to corrosion, and it currently makes up roughly half of all exhaust systems manufactured. Although less common, stainless steel can also be used for parts like wheels and the lower car structure, reflecting a commitment to higher-quality, long-lasting vehicles.